Remember when Aussie’s weren’t wearing masks because of Covid, but because we had the worst air pollution in the entire world? It’s hard to believe that was only a few months ago, but the bushfires that ravaged an area the size of Poland (12.6 million hectares) released over 400 megatonnes of carbon dioxide into the atmosphere.

That’s Australia’s average annual carbon dioxide emissions in just three months. And it's not like we turned off the coal-fired power stations or stopped ripping stuff out of the ground - so it's additional carbon into a world already burning dangerously.

Long before the fires, we pledged that every Citizen Wolf Tee produced would be carbon neutral, but as we watched the destruction unfold we didn't want to just walk the walk, but leap forwards five steps at a time.

PUTTING OUR MONEY WHERE OUR MOUTH IS.

So in January we pledged to 5x our carbon offsets for every Tee sold in 2020, and we’re pretty chuffed to say that as of June 30 we’ve already offset 50 tonnes of CO2e – twice as much as we did for the whole of 2019 and we've still got 6 months to go!

As of June 30 we’ve already offset 50 tonnes of CO2e – twice as much as we did for the whole of 2019

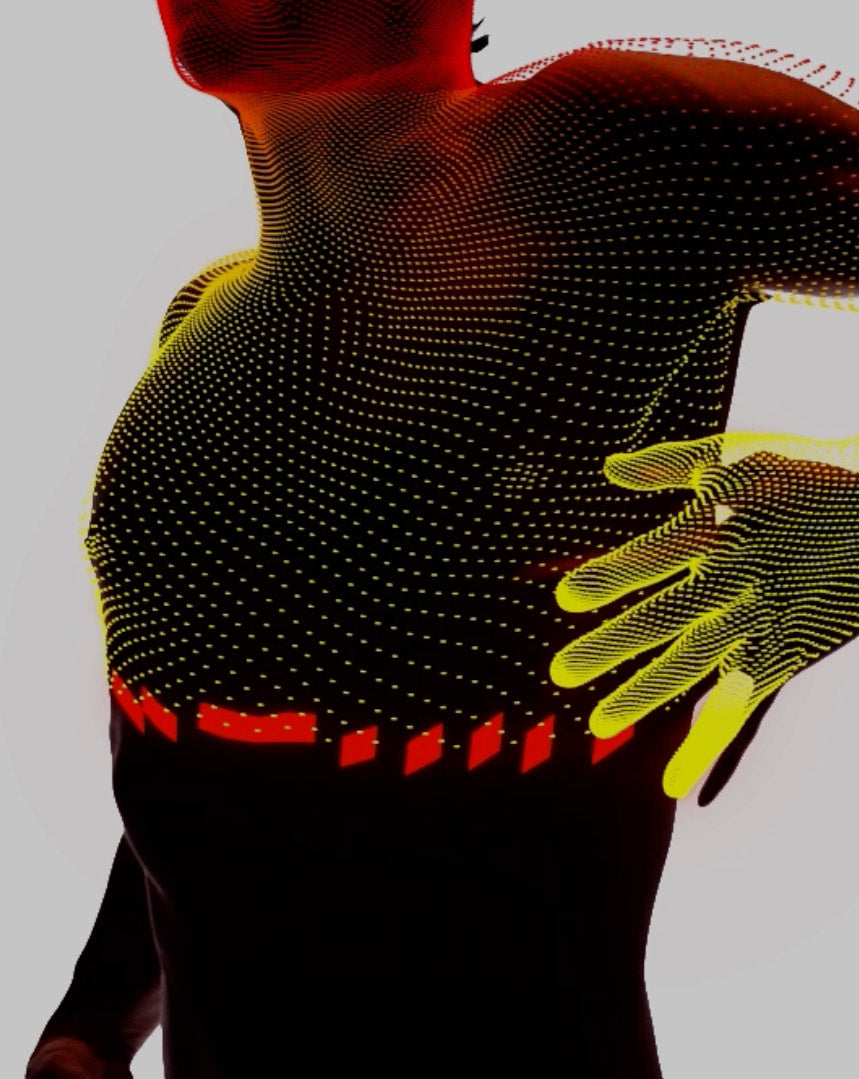

To put this into perspective, that’s approximately the mass of 7.5 elephants (which finally explains the gorgeous photo above by David Yarrow). Or, if you prefer to keep your carbon metaphors limited to things that also produce carbon, that's equivalent to powering 17 homes over the same period.

To break it down even further, for every single Citizen Wolf Tee made we offset enough carbon to drive ~11 km, which if you're also in Sydney might even get you to Taronga Zoo to see a real elephant.

HOW TO EAT AN ELEPHANT

We've obviously got elephants on the brain, but you know what they say about eating one? Do it slowly, one bite at a time. And it's exactly the same with doing y/our bit to save the planet.

Carbon offsetting is one thing (to digest), but there are also 5 key steps involved in the manufacturing process of a Tee where we’ve worked hard to systemically reduced our footprint.

The true cost of a single fast fashion Tee in carbon is closer to 5.6kg CO2e – equivalent to 22x its weight in carbon! Citizen Wolf Tees by contrast use 48% LESS carbon.

From farm to hanger, loads of CO2e is consumed in the fashion supply chain with 4.3kg of CO2e emitted from manufacturing a single 250 gm Tee, according to MIT Material Systems Lab. And if that doesn’t leave a bad taste in your mouth, the Ellen McArthur Foundation found that a ginormous 73% of the Tees made every year will end up in landfill or be incinerated within 12 months due to poor quality and poor forecasting (aka overproduction).

What. The. Actual. Fuck?!

So when we add this overproduction into the calculation, the true cost of a single fast fashion Tee in carbon is closer to 5.6kg CO2e – equivalent to 22x its weight in carbon!

For perspective, that's the same amount of energy used to charge your phone every single day for 2 years to make one single Tee! Talk about a wake-up call...

By contrast Citizen Wolf Tees emit 48% LESS Carbon than their fast fashion equivalent, so they don’t cost the Earth (literally). And if you're interested in how we arrived at these numbers, check the appendix below.

THE ELEPHANT IN THE ROOM

Whilst we each have a personal responsibility to consume consciously, as a manufacturer we have a moral responsibility to change the way clothes are made. And yes, this means addressing the elephant in the room – the default model of forecast driven mass-production is so very clearly broken.

Our mission here at Citizen Wolf is nothing less than re-engineering the way clothes are made at scale to be both carbon negative and custom fit to every body. We are out to prove that an alternative model to oversupply and landfill is both possible and viable but also desirable.

The future of fashion really does start with the perfect tee, so start running with the wolves today.

APPENDIX

1. Farm

Regular cotton produces ~1.3kg CO2e / Tee from the use of pesticides, fertilisers and harvesting alone (Stockholm Environment Institute, 2005). By contrast Citizen Wolf uses certified organic cotton from India which has a 30% lower carbon footprint of only ~1 kg / Tee mainly due to zero chemicals but also more manual farming practices (Stockholm Environment Institute, 2005).

2. Textiles

Ginning, spinning, drying, carding and milling the cotton plant into the luxurious jersey you know and love is an energy-intensive process contributing a further 1.9kg CO2e / Tee. Whilst organic cotton is undoubtedly better on the farm, the process of creating the yarn is no different to regular cotton. That said, organic cotton generally uses less chemicals and dyes resulting in a 22% reduction of carbon to 1.5kg CO2e / Tee (Stockholm Environment Institute, 2005)

3. Cut & Sew

The “cut, make, trim” transformation of cloth into clothes accounts for 0.46kg CO2e / Tee for fast fashion, mostly from dirty coal-fired power stations in less developed countries where they’re made (like Bangladesh). And whilst most of Australia is similarly powered by coal, here at Citizen Wolf we use certified renewable energy from RedEnergy who further offset every tonne of CO2 generated with their own hydropower for double the positive impact. This reduces the carbon used at our purpose-built factory by over 90% to only 0.04 kg (ie 46 grams) CO2e / Tee mostly due to threads, labels and tags. Really.

4. Retail

Once clothes are made, more carbon has to be spent getting them into shops and into your wardrobe. Whilst logistics and the energy in the shop varies greatly between doors, it averages around 0.64kg CO2e / Tee.

Besides using renewable energy, Citizen Wolf have also switched to compostable satchels and minimal packaging, reducing cardboard usage by 50%. This means less weight and ultimately less carbon expelled by our couriers.

5. Overproduction

The final component that often is missed when calculating most brand’s carbon footprint is the cost of overproduction. Wasted inventory is around ONE IN EVERY THREE garments made globally that end up either incinerated or landfilled and which adds a further 1.3kg CO2e / Tee. As Citizen Wolf Tees are made to order, we have zero overproduction.